With the increase of the speed and width of the paper machine, the bag ventilation in the traditional drying section can't meet the normal operation of the paper machine. When the paper leaves the drying cylinder and passes through the vacuum roller along the dry web, it will wrinkle and bubble. Finally, it will form a loop, fold or lotus leaf edge on the paper. At this time, it is necessary to use the web stabilizer, which is mainly used in the press section, the paper cylinder and the drying section of the medium and high speed paper machine.

The function of the web stabilizer

The main function of the web stabilizer is to improve the stability of the web operation and reduce the end breakage and paper defects. The single hanging drying cylinder group of the drying section can not only improve the stability of the sheet operation, but also improve the evaporation speed of the sheet water. At present, the imported high-speed paper machine is generally equipped with a web stabilizer, which is the key component of the paper machine speed-up stabilizer, and this configuration is one of the key components of the paper machine speed-up.

Structural principle

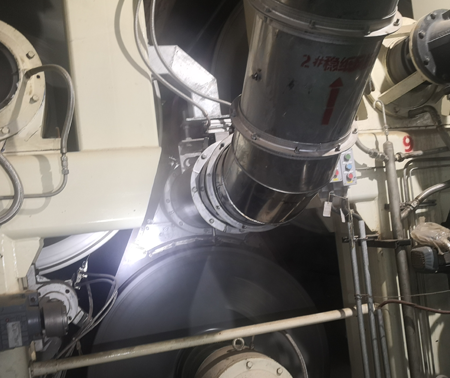

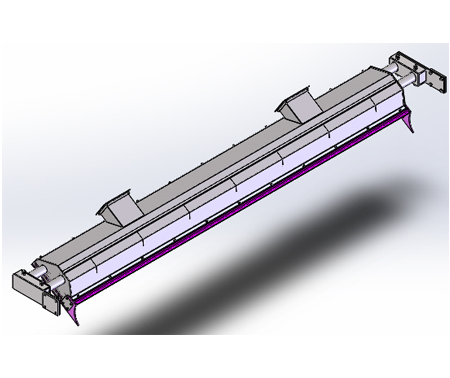

The web stabilizer is mainly composed of fan and web stabilizer. The web stabilizer is generally close to the back of the net or blanket. There is a pressure chamber in the internal structure. The high-pressure air is ejected from the nozzles around the bellows. With the high-speed operation of the paper machine, the nozzle around the area is ejected. With the high-speed operation of the paper machine, the area is stable.

Notes on making and installation of web stabilizer

1. The width and angle direction of the air vent must be in strict accordance with the requirements of the drawings

2. The welding must be firm, especially the spot welding of the air vent

3. After fabrication, the welding slag must be cleaned, all sharp corners shall be polished, and the surface close to the wool cloth shall be polished

4. Before installation, it must be cleaned as a whole to ensure that there is no impurity

5. During installation, pay attention to the protection of roll, woolen cloth, mesh and air vent to prevent bumps and scratches

In order to make the web stabilizer have a good performance, usually the dry mesh must have a suitable air permeability. If the air permeability is too small, there is not enough vacuum between the dry net and the stabilizer; if the air permeability is too large, it is easy to produce harmful air flow.

![]()

| Mobile: + 86-15965759999 | |

| Tel.: + 86-0635-2531988 | |

| Email: fengxin@cnfengxin.cn | |

| Address: Hi tech Industrial Park, Linqing City, Shandong Province (shilitun, Xinhua office) |