Due to the use of closed hood with hot air, the modern large-scale high-speed paper machine is a relatively closed area composed of upper dry mesh, paper web and lower dry cylinder in the drying section composed of double row drying cylinder and double dry mesh, which is called "pocket area". With the movement of the dry fabric, the dry fabric carries a lot of air, and a positive pressure area is formed between the dry fabric and the blanket roller. The positive pressure air flow (the high humidity air in the closed hood) enters the pocket area through the dry fabric, and the humidity in the pocket area increases. The positive pressure air flow is affected by the speed of the paper locomotive, the air permeability of the dry blanket, the position of the blanket roller and other factors, so it is difficult to control the amount of air entering the pocket area. The high permeability dry fabric sucks excess air into the pocket area, excessive air makes the pocket area "overpressure", air escapes from both ends, causing the web shake.

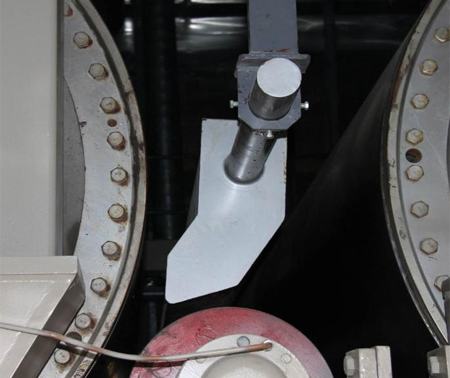

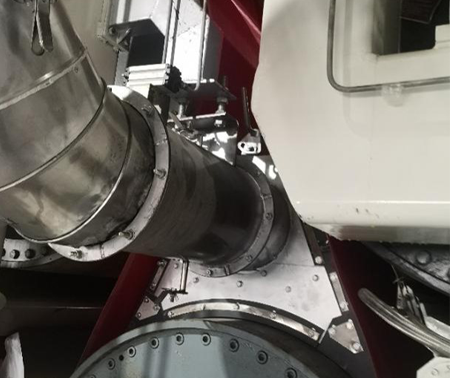

High speed hot air closed hood

In order to avoid the web shaking, the low permeability dry fabric is used to prevent the air from entering the pocket area. However, the low permeability dry fabric has many disadvantages, such as the increase of humidity in the pocket area, the lower humidity of the web edge than the middle part, the lower drying rate, the uneven drying of the web and other paper defects.

The suction effect of dry blanket must be controlled to reduce the adverse effect of suction, and the dry air must be sent into the pocket area to achieve the balance of pocket area.

The ventilation effect of the pocket area is affected by the production speed and the paper grade. Usually, the low-speed and high brightness paper grade uses the dry fabric with high permeability and a relatively simple pocket area blow box to avoid the paper shake.

Requirements for high-speed pocket area blow box:

1) balance and control the air flow in the pocket area

The high-speed pocket area blow box requires that the pocket area must be kept in balance, and the high-permeability dry mesh is used without paper web shaking. Therefore, the air brought by the dry mesh must be blocked at the entrance during the production process, and cannot enter the collection area of the dry mesh and blanket roll.

2.) the humidity in the pocket area is low and uniform

Generally, when the pressure of the drying cylinder is lower than 207kpa, the humidity in the pocket area is 0.18kg water / kg dry air; when the pressure is higher, it is 0.2kg water / kg dry air, and the banner fluctuation should not exceed 0.2kg water / kg dry air.

3) be able to correct the moisture distribution of the paper roll CD

There are some limitations in correcting the moisture content of CD, because the moisture content of CD is also affected by the transverse air flow. Generally speaking, when the moisture content of finished paper is 8%, the moisture distribution of CD can be corrected by 2%. Modern high-speed paper machines are generally equipped with air volume regulating valves to control problems such as over drying of paper web edges.

4.) send the hot air to the place where the high-speed hot air hood produces moisture

The air flow in the pocket area exchanges slowly with the outside, and the drying of the paper web has been greatly affected. The moisture distribution of the paper web is uneven, and the moisture on the edge of the paper web is less, while the middle part is more. In order to make the paper machine operate stably at high speed and improve the problem of uneven transverse distribution of the paper web, according to the different types of paper and the speed of paper-making, a variety of paper blower boxes with different functions are set up. The high-speed hot air is sent into the pocket area by the nozzle, and the saturated humid air in the pocket area is replaced by the dry hot air, so as to improve the drying rate, the moisture distribution of the paper web and the drying effect. The combination of pocket ventilation and dry fabric can improve the drying capacity by 20%.

![]()

| Mobile: + 86-15965759999 | |

| Tel.: + 86-0635-2531988 | |

| Email: fengxin@cnfengxin.cn | |

| Address: Hi tech Industrial Park, Linqing City, Shandong Province (shilitun, Xinhua office) |