With the promotion of low-carbon and energy-saving economic model, hot air drying equipment manufacturers are driven by energy saving and low-carbon environmental protection. When we reexamine the energy consumption in the paper making equipment, the most promising energy-saving research is the drying section. The energy consumption of the drying part of the paper machine mainly consists of the following three parts: the ventilation of the hood; the steam consumption of the drying cylinder; and the rotating roller parts of the drying part.

The ventilation of the hood has a large space for energy saving. The ventilation system of the drying part of the paper machine of the hot air drying equipment includes airtight hood, hood exhaust system, hood air supply system, heat recovery system and other equipment. In the limited space of the airtight hood, the air state and circulation in the drying section are adjusted and controlled by the exhaust and air supply of the airtight hood. Therefore, it is an important measure to accurately control the air system in the hood to ensure even moisture and save energy when the hood is sealed.

Through many times of practice, we have carried out the following research on the ventilation drying of the paper sheet in the hood. The paper sheet from the pressing part has gone through three stages of drying in the hood.

1. In the heating and accelerating drying stage of the paper, the newly entered paper is heated rapidly at the front of the hood, where the non combined moisture in the paper is evaporated rapidly, and the air discharged from this area in the drying cylinder bag area has low temperature and high humidity. In the accelerated drying stage, the drying degree of the paper is increased from 43-52% of the air intake hood to 60-65%, and the paper temperature is increased from 30 ℃ to 65 ℃. There is a lot of water evaporation on the paper here.

2. In the constant temperature and constant speed drying stage, when the temperature of the paper increases, the unconjugated water evaporates, and the combined water begins to evaporate, and a large amount of wet air is taken away from the bag area of the drying cylinder, and the temperature is high. At this stage, the paper dryness increases from 60-65% to 75-85%, and the paper temperature increases from 65 ℃ to 92 ℃. In this paper, the moisture evaporation is the most, when the temperature is increased greatly, the drying cylinder consumes a lot of steam heat energy, and the temperature sequence of the drying cylinder rises to a higher temperature. Hot air takes most of the moisture away from the page.

3. Jinan hot air drying equipment in the paper cooling and speed reduction drying stage, the paper of non combined water evaporation in constant temperature and speed at the same time combined water has been difficult to evaporate out, the bag area of the drying cylinder has less wet air but higher air temperature. The dry degree of the paper is increased from 75-85% to 90-97%, and the paper temperature is reduced from 92 ℃ to 80 ℃ (because after the paper leaves the hood, it needs to enter the dispenser, and the higher temperature makes the paper strength low). The moisture in the paper is further evaporated, which is close to the required dryness of the finished product. After the paper leaves, it is dried for sizing, and then dried for finishing, which is the finished product.

Among them, the steam energy saving of drying cylinder has been greatly improved. The steam consumption has been greatly reduced by means of heat pump and multi-stage steam supply. Now some enterprises have been able to consume 1.8 tons of steam / ton of paper. The transmission of drying cylinder also has large energy-saving research, frequency conversion, direct drive of guide roller and other square tests. It effectively reduces the large starting power needed by the dryer when it starts, and the high-energy consumption running characteristic of the lower load when it runs normally.

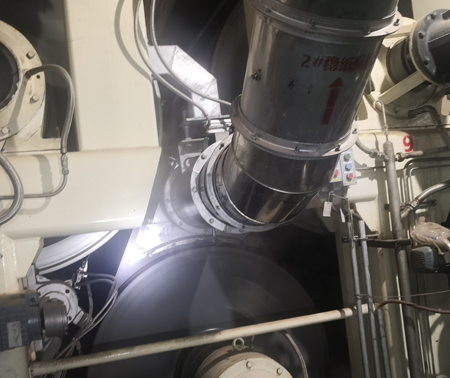

![]()

| Mobile: + 86-15965759999 | |

| Tel.: + 86-0635-2531988 | |

| Email: fengxin@cnfengxin.cn | |

| Address: Hi tech Industrial Park, Linqing City, Shandong Province (shilitun, Xinhua office) |