There are many people who know about HRR but don't know what its main components are. Let's analyze it today.

Loading part

The structure of waste heat recovery equipment is relatively simple, which is composed of material groove and roller. The fabric enters the material groove, takes chemical materials, and then presses the surplus chemical materials through the roller. Therefore, the chemical materials on the cloth are very uniform, which is the prerequisite for obtaining high-quality set cloth.

What we should pay attention to here is whether the pressure on the left and right sides of the roller is consistent. Otherwise, the side with small pressure will be loaded with more materials, while the side with large pressure will be loaded with less materials, and the cloth will have quality problems such as left and right inconsistency.

Weft leveler

Mahlo rfmc94h photoelectric finisher is equipped on the shaping machine of Jinan waste heat recovery equipment. There are four sets of sensors on the Mahlo photoelectric finisher. Each set of sensors includes two parts of light-emitting and light-sensitive. The weft angle can be distributed through photoelectric effect. In the action part, the hydraulic system is used. When the signal of weft angle is sent back to the control board, the control board will send out a command to drive the hydraulic system to adjust the angle of the curved roll or the straight roll so as to correct the weft angle. Specifically: when there is a difference between the cloth center and both sides, the curved roller will act; when there is a difference between the left side and the right side, the straight roller will act.

Chain part

The stretching of the cloth on the setting machine is generated by the chain. The chain of the setting machine is driven by a high-power motor close to the cloth falling place. The chain is equipped with a needle plate. When the cloth enters the chain, the brush wheel on the cloth pressing wheel presses the cloth on the small needle on the needle plate. The cloth can enter the oven under the transmission of two chains. The chain of this machine is different from that of other machines. It can control the stretching of each clip separately, so as to achieve good results. However, some machines can not adjust each clip, only grow square or trapezoid.

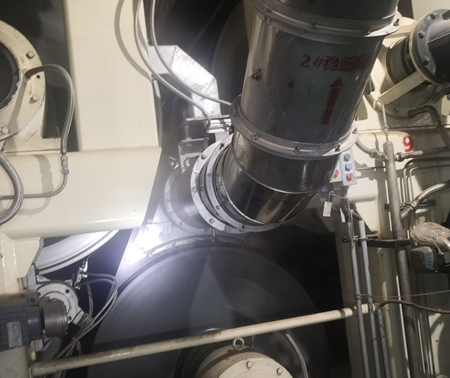

Oven body

Generally, there are eight sets of ovens in the setting machine, and the air is continuously sprayed on the cloth surface by the small holes on the star air-jet frame under the blowing effect of the circulation fan. After the hot air contacts the wet cloth, the temperature drops and the humidity increases, and it is discharged from the large hole on the star air jet frame, and then it is recycled after passing through the filter screen and being heated by the heat exchanger. The heat exchanger is located under the filter screen. The heat coal body is hot oil. There are many thin fins on the heat exchanger to produce efficient heat exchange.

![]()

| Mobile: + 86-15965759999 | |

| Tel.: + 86-0635-2531988 | |

| Email: fengxin@cnfengxin.cn | |

| Address: Hi tech Industrial Park, Linqing City, Shandong Province (shilitun, Xinhua office) |